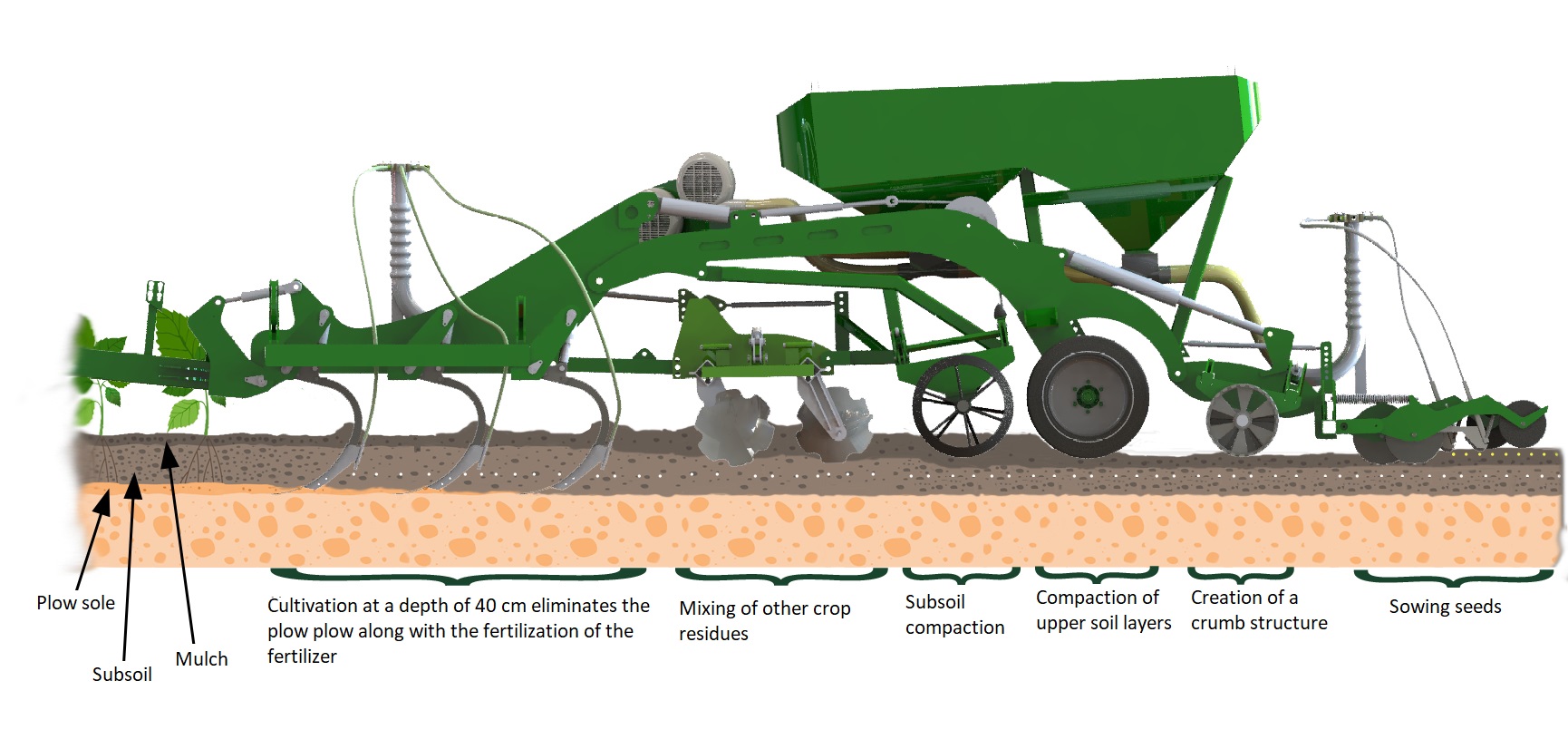

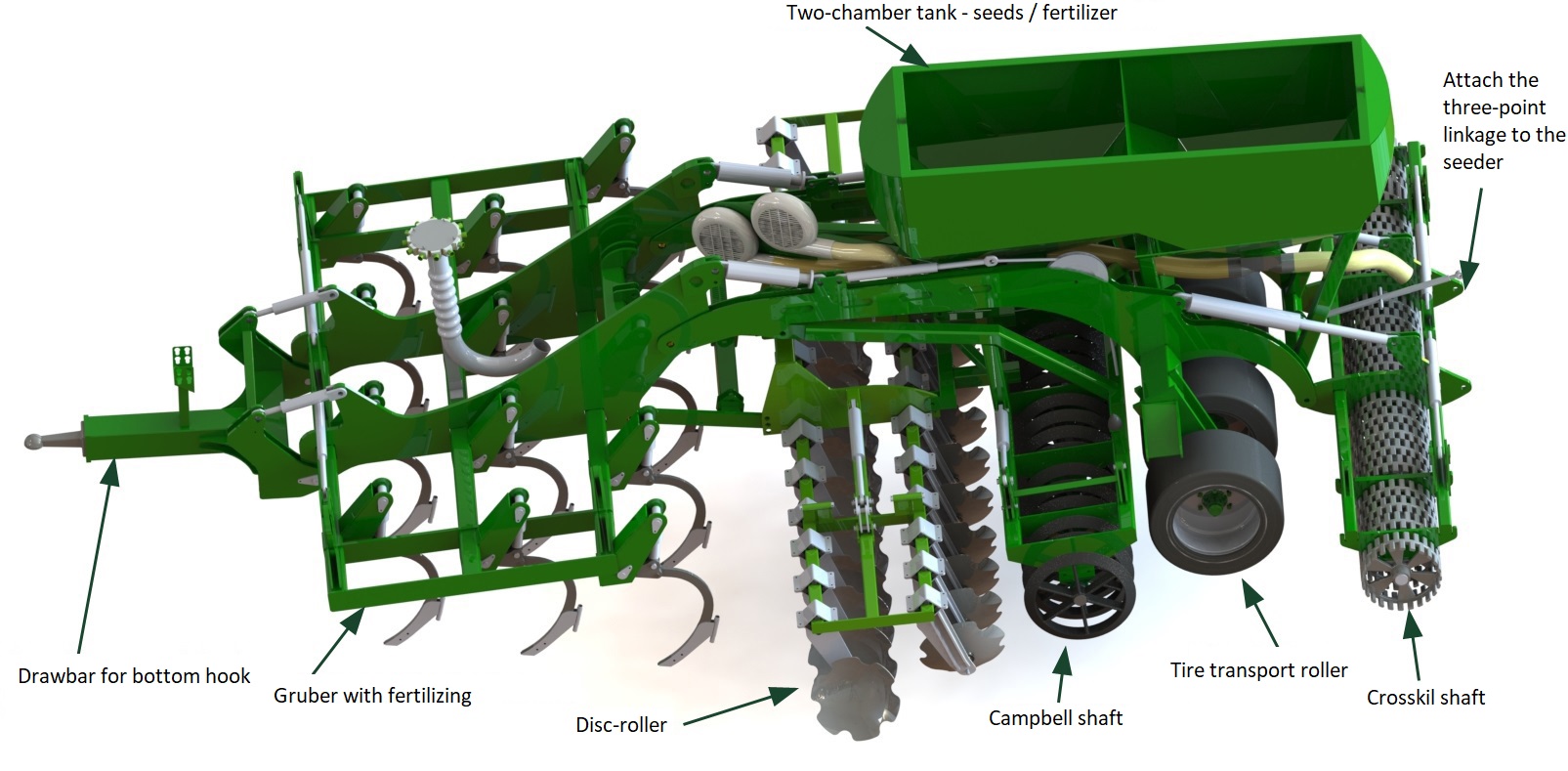

The cultivation and seeding aggregate for non-plowed sowing is composed of a grubber in which the fertilizer is introduced, the cultivation part (disc harrow), Campbell subsoiler, tire shaft or alternatively the Crosskil crushing roller and sowing coulters. The two-chamber reservoir in the seed section will accommodate 1200 kg of wheat, while in the fertilizer part, 1200 kg of ammonium phosphate.

Deep cultivation section

The first working section is a 3-bar grubber with teeth spaced every 25 or 30 cm. Teeth that can work at max. 35cm deep, they are protected against stones by hydraulic cylinders and a gas-oil battery, which allows you to adjust the pressure depending on the depth of work and soil compactness or using springs. The gruber may be fertilized with fertilizer, which is particularly recommended when sowing beet and rape. The depth of the fertilizer can be adjusted in the entire soil profile.

Leveling section

The leveling section can be equipped alternatively with a disc harrow, sprout or spring. A 3-point suspension system allows suspension of any tool. These elements are suspended independently of the depth of the grubber's work. The working depth of the plateau / echidend is regulated in relation to the campbell shaft. Plate is equipped with 2 rows of corrugated plates with a size of 600mm mounted on spiral springs.

Spike consists of 4 journalled rollers fitted with blades, whose task is shallow soil leveling after cultivation.

Campbell

The Campbell shaft is responsible for composting the subsoil. Depending on the soil, it is possible to choose the angle of the shaft cone. The heavier the soil, the more sharply this angle should be. The Campbell shaft is also an element that sets the working depth of the disc harrow. It is suspended on ropes, thanks to which it works without exposing the elements of the chassis support frame to overloading, thus increasing the reliability of the machine.

Front tire shaft

The front tire roller plays a double role. First of all, it serves as transport wheels. Its other role is to densify the shallower soil layers, preparing it for sowing seeds.

Crosskil / tire shaft

The last replacement element is the crosskill shaft or alternatively a tire shaft that is in the offset with the front tire roll. The crosskil pivot roller compacts shallow soil layers and crushes the remaining soil sections from the more upstanding crop sections, ideally thus preparing the soil before sowing the seeds.

Alternatively, instead of a pin shaft, a rear tire shaft can be used for surface compaction of the soil. This shaft is arranged in the so-called off-set to the front tire shaft.

Sowing section

The last working element of the Tygrys unit is the sowing section. Due to the standardized three-point linkage (TUZ), it is possible to hang any seeding attachment of any manufacturer. It can be both a mechanical seed drill, a pneumatic drill using an integrated tank, a precision seeder and a planter.

Seed drill

Pneumatic seed drill for sowing of cereals, rape and legumes of "SMELA" Agricultural machinery production is equipped with innovative sowing coulters that are ideally placed on the Mesozoian soils. The spacing of the coulters is adjusted to the spacing of the teeth in the grubber and can be in the case of cereals 12.5 cm or 15 cm, while in the case of rape seeds 25 cm or 30 cm.

Single-seed sowing machine

The seed drill suspended on the aggregate allows the sowing of plants that require very precise placement of the seed in the soil. Thanks to this, the Tygrys tillage and seeding unit allows for sowing beet, maize and rapeseed in one pass technology, thus saving water that is so valuable nowadays. In the case of sowing maize every 75 cm, we recommend that the distance between the teeth in the grub is also of this value. As a result, the teeth on the rear beam of the grubber grow a soil belt that coincides with the sowing sections in the precision seeder. By sowing fertilizer in these strips, we get an effect similar to Strip-till.

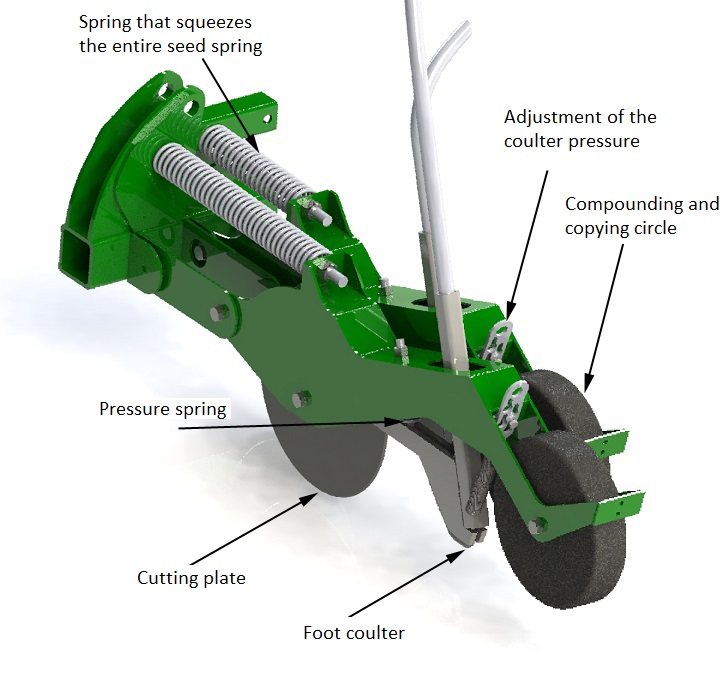

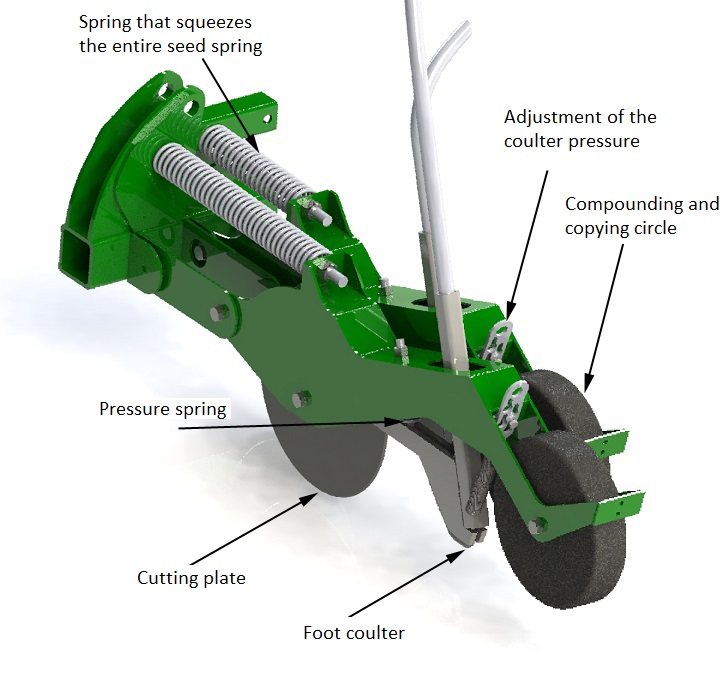

The concept of the sowing coulter

Our innovative sowing coulter is the perfect solution for mosaic soil. It is composed of one centrally fixed plate, whose task is to cut up crop residues, a foot squeegee, which places the seed in the furrow and a stamping-copying wheel. The sowing coulter is pressed by a spring, thanks to which it is possible to place the grain at various depths depending on the type of soil so that the grain goes deeper into the sand and into the coarse clay, which ensures even emergence.

Agronomic advantages of the sowing coulter

- One large centrally placed plate cuts the remaining harvest residue

- The footed beetle forms a furrow and kneads its bottom, thanks to which the grain falls to perfectly prepared moist soil.

- The copying-and-caking wheel covers the grain and presses it down to the ground, which increases water sucking.

Mosaic soils have always been a problem during sowing. It happens that on one part of the field there are sands and on the other clay. When sowing at a constant depth across the entire patchy field, often the emergence is very uneven.Our innovative sowing coulter, thanks to its unique design, automatically adjusts the depth of sowing to the type of soil in which it sows. As a result, grain is sown in the clay in shallow clay, and deeper in the sands. This ensures even emergence, which increases the profitability of the plantation.

An innovative way of growing soil

| Tygrys |

3.0 GTWS |

4.0 GTWS |

4.5 GTWS |

| Length |

9m |

9m |

9m |

| Working width |

3m |

4m |

4.5m |

| Transport width |

3m |

3m |

3m |

| Height |

3.15m (without markers ) |

3.15m (without markers ) |

3.15m (without markers ) |

| Mass |

8800kg |

10600kg |

11000kg |

| Demand for power |

220KM |

300KM |

350KM |

| Working speed |

10km/h |

10km/h |

10km/h |

| Tank capacity* |

1200kg/ 1200kg |

1200kg/ 1200kg |

1200kg/ 1200kg |

| Number of hydraulic connector pairs |

3 |

4 |

4 |

| Hook |

K80/ TUZ kat. 3 |

K80/ TUZ kat. 3 |

K80/ TUZ kat. 3 |

| Number of teeth** |

10/12 |

13/16 |

15/18 |

| The distance between the teeth |

75cm/ 90cm |

75cm/ 90cm |

75cm/ 90cm |

| Frame clearance |

80cm |

80cm |

80cm |

| Number of coulters |

20/24 |

27/32 |

30/36 |

| Distance between coulters |

12,5cm/ 15cm |

12,5cm/ 15cm |

12,5cm/ 15cm |

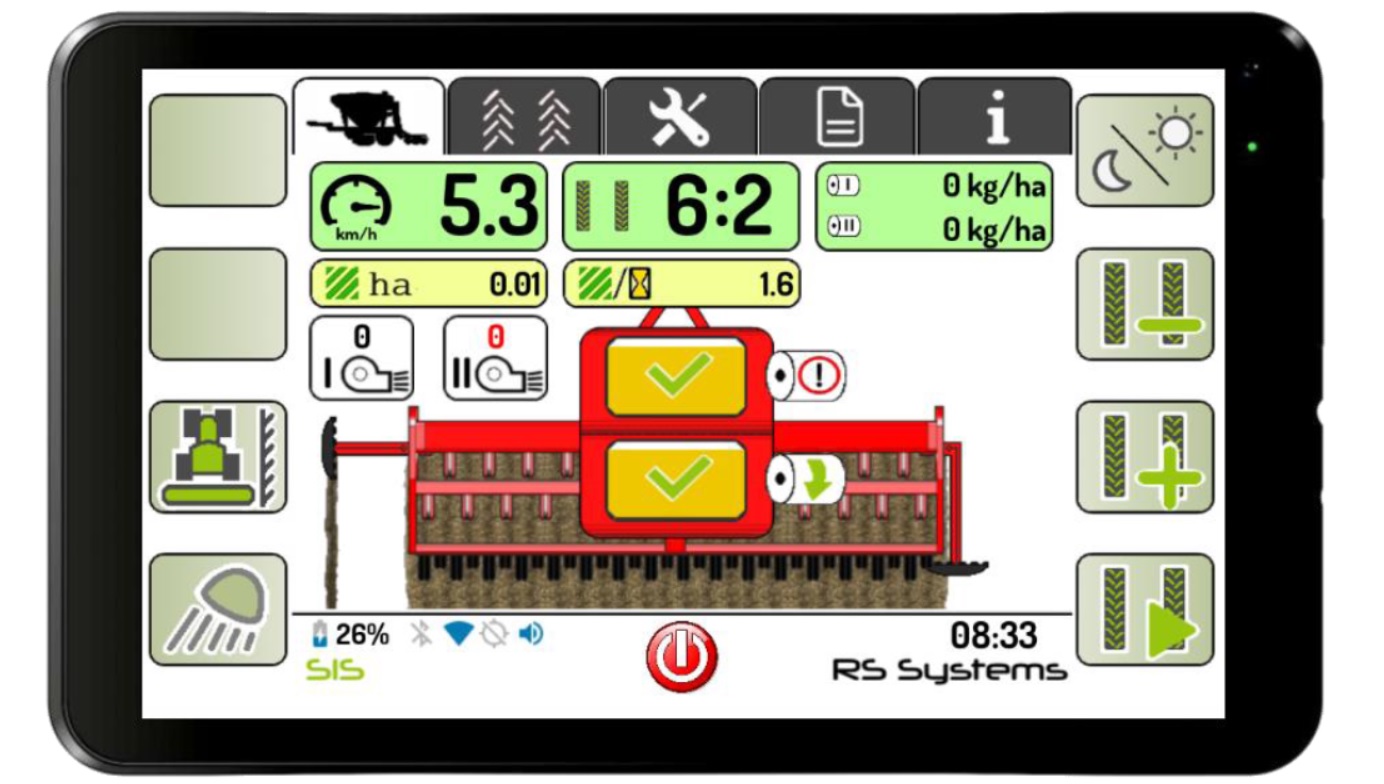

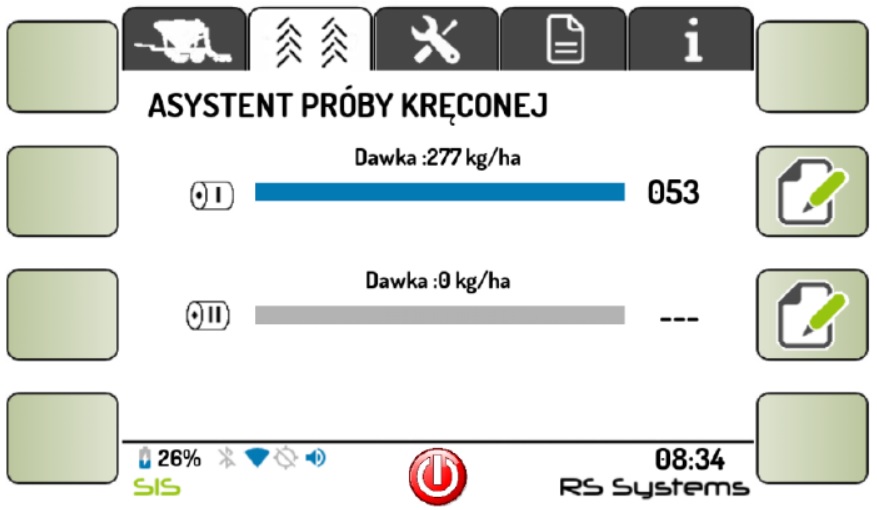

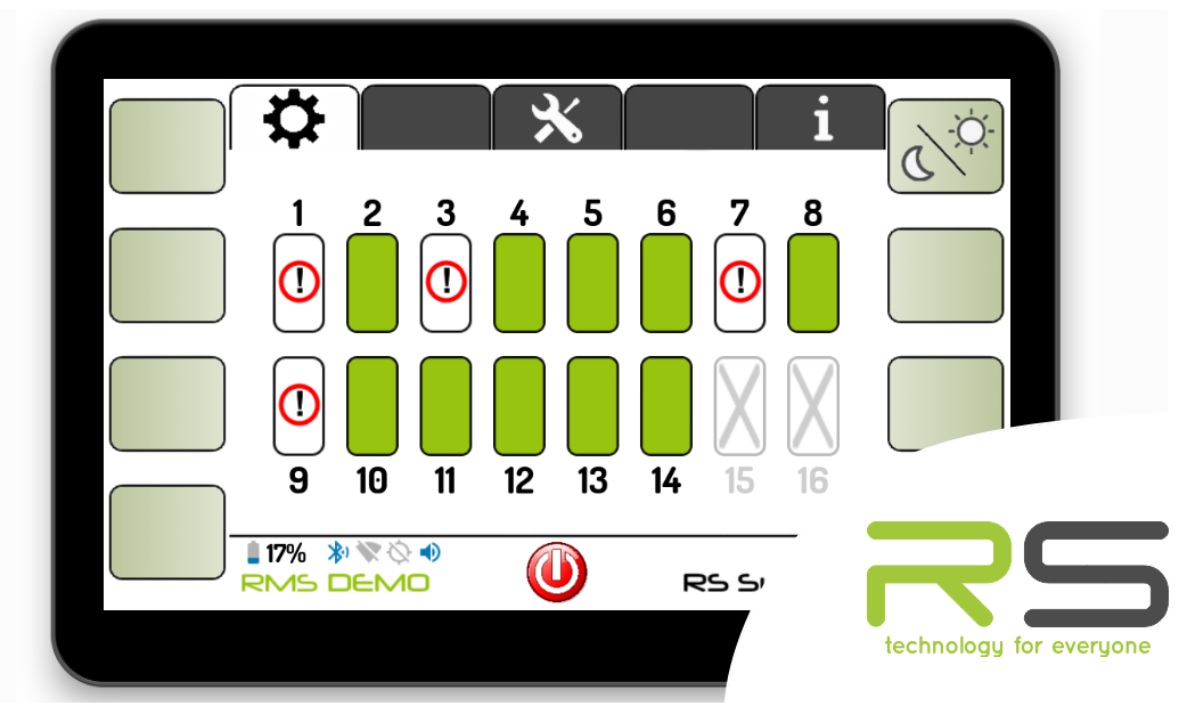

Controller RS-System

All operating parameters of the cultivating machine can be controlled by the RS-System controller.

A 7 or 10 inch tablet with an application displaying all operating parameters.

The tablet that connects wirelessly to the machine can display data such as:- fan speeds- the speed of the sowing devices-speed of work-filling the chambers of the seed and fertilizer tank-automatic installation of tramlines-lighting of work lamps-counting the sown area.And many others

In addition, thanks to the Wi-Fi connection and the calibration test, the adjustment of the dose of seeds is simple and comfortable.

Spreading control RMS

The controller for seed sowing control, with seed flow sensors on each coulter pipe, allows full seed sowing control. These sensors can be mounted both on the seed sowing tubes in the coulters and on the fertilizer sowing pipes.

7 or 10 inch tablet with an application to control the flow of seeds in the tubes

Seed flow sensor mounted on tubes.

Photos

Universal aggregate for sowing cereals, rape, maize.

Universal aggregate for sowing cereals, rape, maize.